Veneer Patterns for Flush Doors

Wood veneer patterns on flush doors range from straight and simple to complex artistic designs. The vertical straight patterns are most common and most budget-friendly. The complex "sketch face" veneer designs will bring a higher cost. Read below to learn more about your veneer pattern options.

Request a quote or email us for pricing. We encourage you to call and speak to our helpful sales staff to answer your questions and to get quotes on your door project.

Veneer Cutting Methods

The individual pieces of veneer sliced from a log are called "leaves". Leaves are kept in the same order they were cut from the log to aide in maintaining the natural grain progression of wood as the veneers are assembled on the faces of doors. The cutting and assembly methods applied to the veneer leaves determine the appearance of the door face.

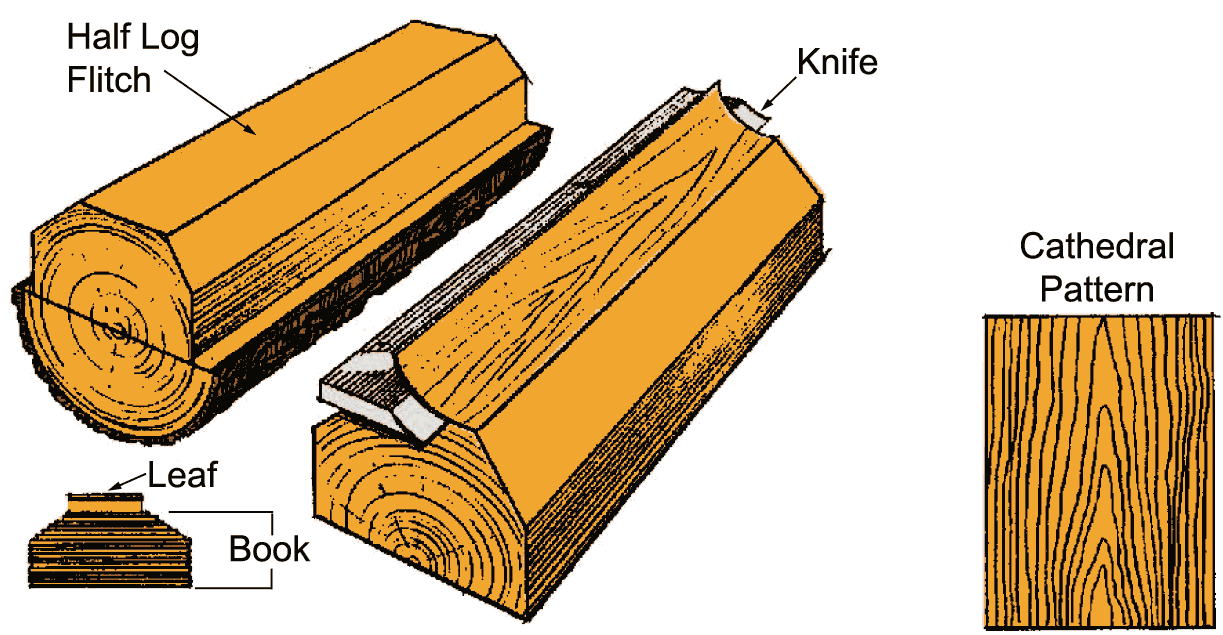

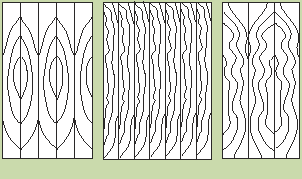

PLAIN SLICED

Leaf width depends on log size and placement in flitch.

PLAIN SLICED VENEER

Plain slicing is the method most commonly used to produce veneers for architectural flush doors. The slicing of the flitch is done parallel to a line through the center of the log. The result of this cut will yield mostly cathedral grain patterns and some straight grain. The veneer leaves are kept in the same order they are cut - like a book - and can be assembled onto the face of the door with a very seamless, natural progression of wood grain pattern from one leaf to the next.

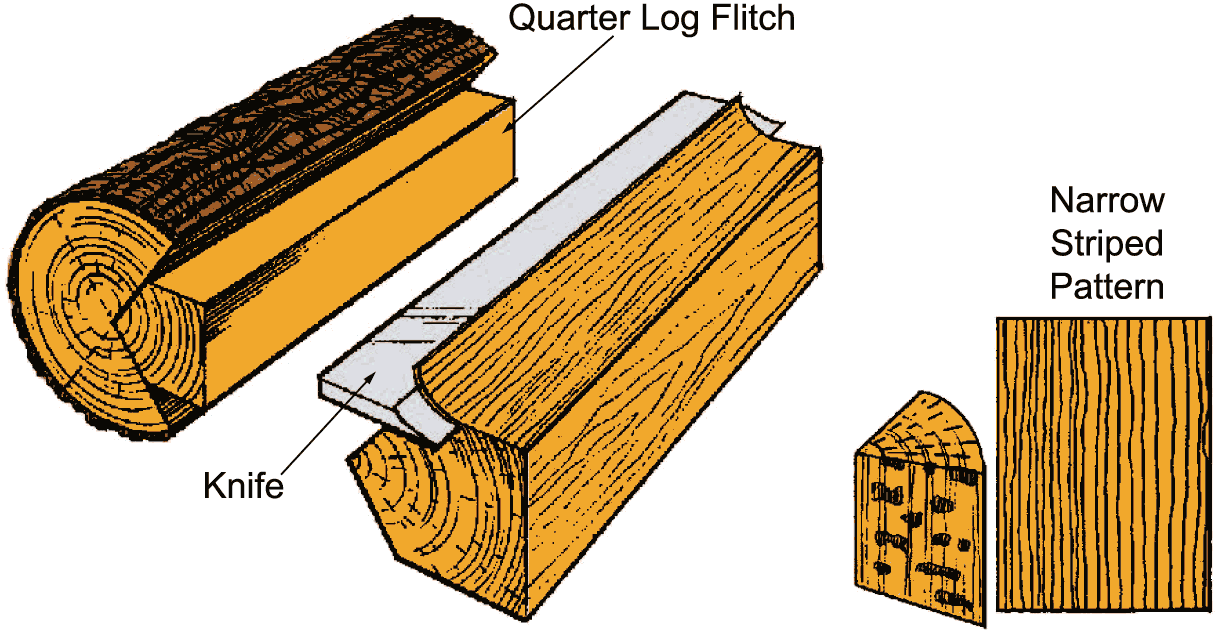

QUARTER SLICED

Produces narrow stripe grain pattern with "flakes", particularly in oak.

QUARTER SLICED VENEER

Quarter slicing simulates the same grain pattern as quartersawn solid lumber. A quarter log, or flitch, is mounted so the slicer cuts the log at a 45° angle to the axis lines of the log. This creates a striped, mostly straight grain effect. The Medullary Rays that are naturally very pronounced in White Oak or Red Oak logs will become a prominent visual characteristic of quartersawn veneers often referred to as "flakes" or "flecking".

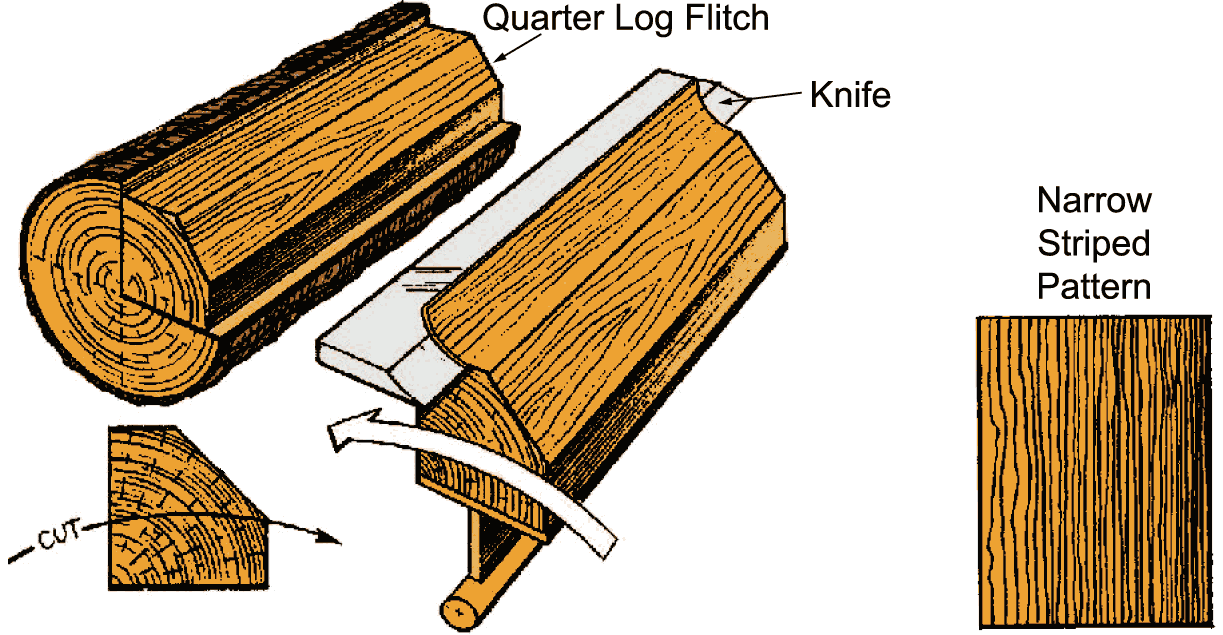

RIFT CUT

Angle of cut is 15° from the radius of the flitch to minimize the ray flake effect that occurs in oak. Comb grain is the portion which has very tight and straight grain.

RIFT CUT VENEER

Rift cut veneers are most commonly produced in Red Oak and White Oak as a special method to minimize the "flake" effect that appears in quarter slicing oak. A quarter log is mounted off center on a lathe and cut at a slight angle from the radius of the flitch. This produces a very tight striped, straight grain pattern without the flakes.

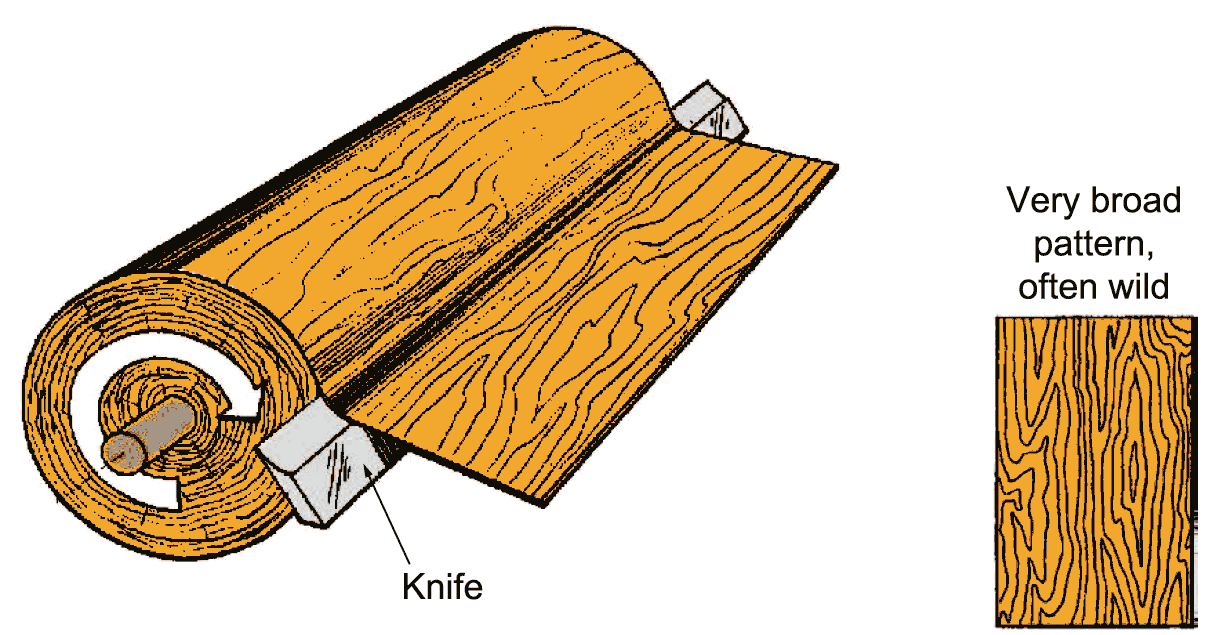

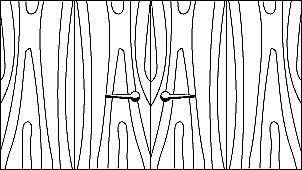

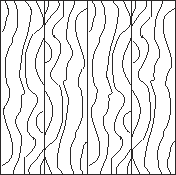

ROTARY CUT

Log is rotated on a lathe while knife slices a continuous veneer.

ROTARY CUT VENEER

Rotary cut veneers are produced when a log is rotated on a lathe while the knife slices a continuous veneer cut. This results in wide sheets of veneer with broad and wild grain patterns. The grain pattern widely varies and makes it difficult to match grain direction at veneer joints. Rotary cut veneers are commonly used to produce economic doors.

Veneer Matching

Once the veneers are cut using one of the methods above, then the leaves must be matched at each joint line. The matching methods below define the way each piece of veneer will be placed next to each other. Each type of match will achieve a certain visual effect in the final appearance of the door.

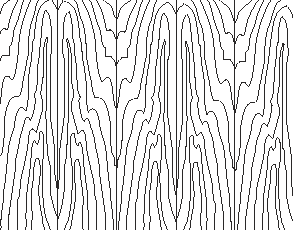

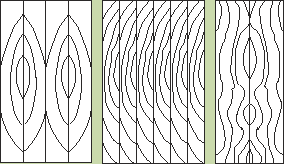

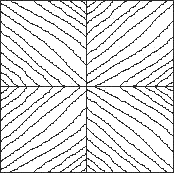

BOOK MATCH

Book match is the most common type of match. Every other veneer leaf is turned over, so two adjacent veneer leaves are "opened"like two adjacent pages in a book. This creates a mirror image pattern at the joint line where the two adjacent leaves meet, making the grain appear to be continuous. Book matching is commonly used with plain sliced veneer, and less often with other slicing methods.

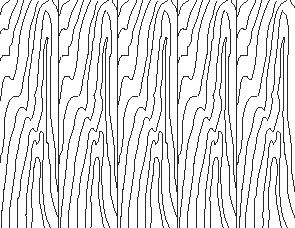

SLIP MATCH

Adjacent veneer leaves are placed in sequence without turning any over. This creates a repeating pattern in the grain. Joints will not show a mirror effect. Slip matching is most commonly used with quarter sliced and rift cut veneer pieces.

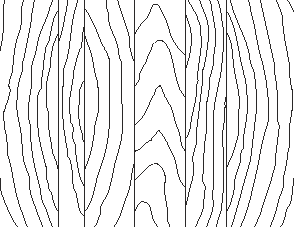

RANDOM MATCH

A random selection of veneer leaves from one or more logs. Each piece of veneer will have random grain direction, so color and grain may vary greatly at joint lines. This creates the appearance of random boards of wood layed side by side.

Veneer Assembly

After choosing a type of match, then the veneer pieces must be assembled across the face of the door in a specified pattern.

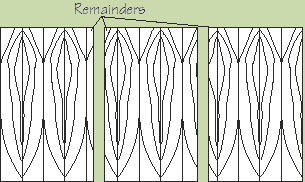

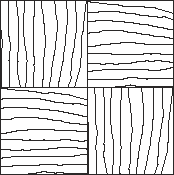

RUNNING MATCH

Veneer pieces are unequal in width. Assembly of the veneer starts at one side of the door and continues across the face using as many leaves as necessary. This creates a non-symmetrical appearance. You may end up with a narrow piece of veneer at the end of the run where there was only a little bit of space remaining to cover the face of the door. This is a cost effective method.

BALANCE MATCH

This method uses veneer leaves that are equal in width across the face of the door. The number of leaves may be even or odd. This creates a symmetrical appearance across the face of the door. However, this method creates some veneer waste so it is more expensive.

CENTER BALANCE MATCH

An even number of equal-width veneer leaves are assemble across the face of the door, so there will always be a joint line in the center of the door. Using only an even number of leaves creates full symmetry on the door. This method creates more veneer waste and is more expensive.

PAIR MATCH

This refers to assembling leaves of veneer across a pair of doors that are in immediate vicinity, like a double-door. This creates continuity across both doors.

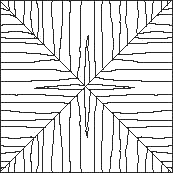

Sketch Face Ideas

Sketch face veneer matches are where patterns can get creative and unique. Below are some examples of sketch face patterns, but you can really arrange veneers any way you want. Sketch face doors are normally for higher budgets.

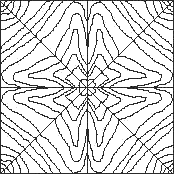

8-piece Sunburst

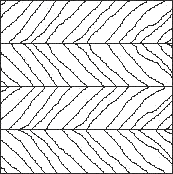

Herringbone or V-Book Match

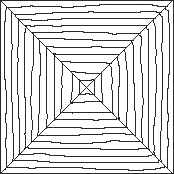

Box Match

Diamond Match

Reverse or End Grain Box

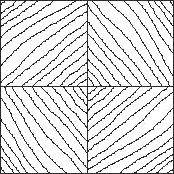

Reverse Diamond

Parquet Match

Swing Match

Book and Butt Match with Border