Beveling a Door

| Door installation Hinge prep - Beveling - Lock prep - Interior Doors Blog - The Ultimate tool for installing prehung interior doors | |

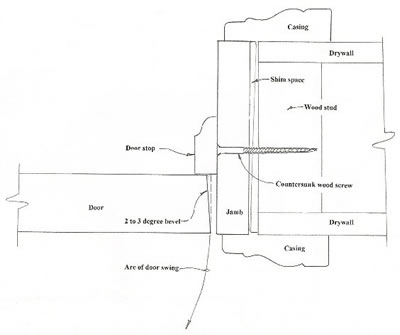

Explanation and instructions for beveling a door When a door swings open or closed there is a radius or arc created by the path of the door. When closing a non-beveled door the leading edge will be closer to the outside corner edge of the jamb than the trailing edge. By machining a bevel on the lockset side of the door both the leading edge and the trailing edge of the door will be the same distance away from the corner edge of the jamb when opening and closing the door. This allows for a tighter fit when the door is in the closed position. 1/8" clearance is recommended between the edge of the door and the edge of the jamb when the door is in the closed position. Any closer than that and you could have problems during humid conditions when the door swells in width and any more than 1/8, the lockset bolt may not reach the strike plate during very dry conditions when the door shrinks in width. |

|

Cross section of door and jamb with door in closed position |

|

|

|

| Beveling a door can be done a number of different ways. The easiest way is to let the company that you order the doors from bevel your doors. You will need to let them know which doors are right hand and which doors are left hand. This will make a difference in which way the bevel is machined (see illustration below). | |

|

|

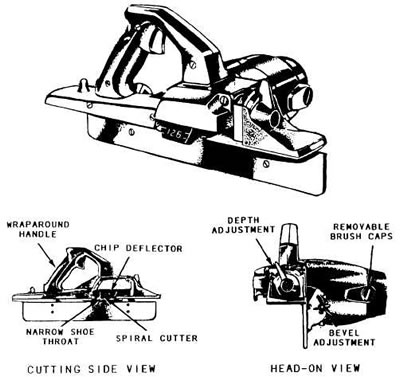

| If you want to bevel the doors yourself you will need 1 of the following machines to do a good job. You will need a portable power plane (see illustration below), a hand plane at least 1-3/4" wide or a portable belt sander. The tool of choice would be a portable power plane. This electric power tool can be set for any degree bevel that you want. Usually one or 2 passes over the edge of the door does the job. If you aren't lucky enough to own one of these then you may have to resort to beveling your doors the old fashioned way with a hand plane. Draw a pencil line on one side of the edge of the door that gets beveled and use that as a guide to know how much wood to remove. Make sure you double check your door swings before starting. You can finish it up by hand sanding the edge. If you have a good touch with a belt sander you can use that instead of the plane. Once again draw a pencil line on one side of the edge of the door to use as a guide for how much wood to remove. | |

Power plane illustrations for door beveling |

|

|

Porter Cable 3-1/4" Power Plane Kit, Model #9125

|

|

|